Technical Parameters

| Frequency: | 15-20kHz |

| Output Power: | 1000W-3200W |

| Supply Voltage: | 230V/50-60HZ |

| Piston Diameter: | 63 mm |

Area of Use

This machine is widely used for ultrasonic welding of plastic products.

- Modular design, PLC control unit

- Product attachment apparatus that can be easily changed according to the product

- Air leakage control

- Output time adjustable from 0.01 to 10 seconds

- Output power and welding time adjustable

- Horn design by product

- Both round and angular parts can be welded

- Robust welding on thin-walled visible parts without markings on both sides Weather and watertight welds

- High weld seam strength

- Short welding times

- Joining parts without leaving any traces on the welding surface, far from aesthetic and visual concerns

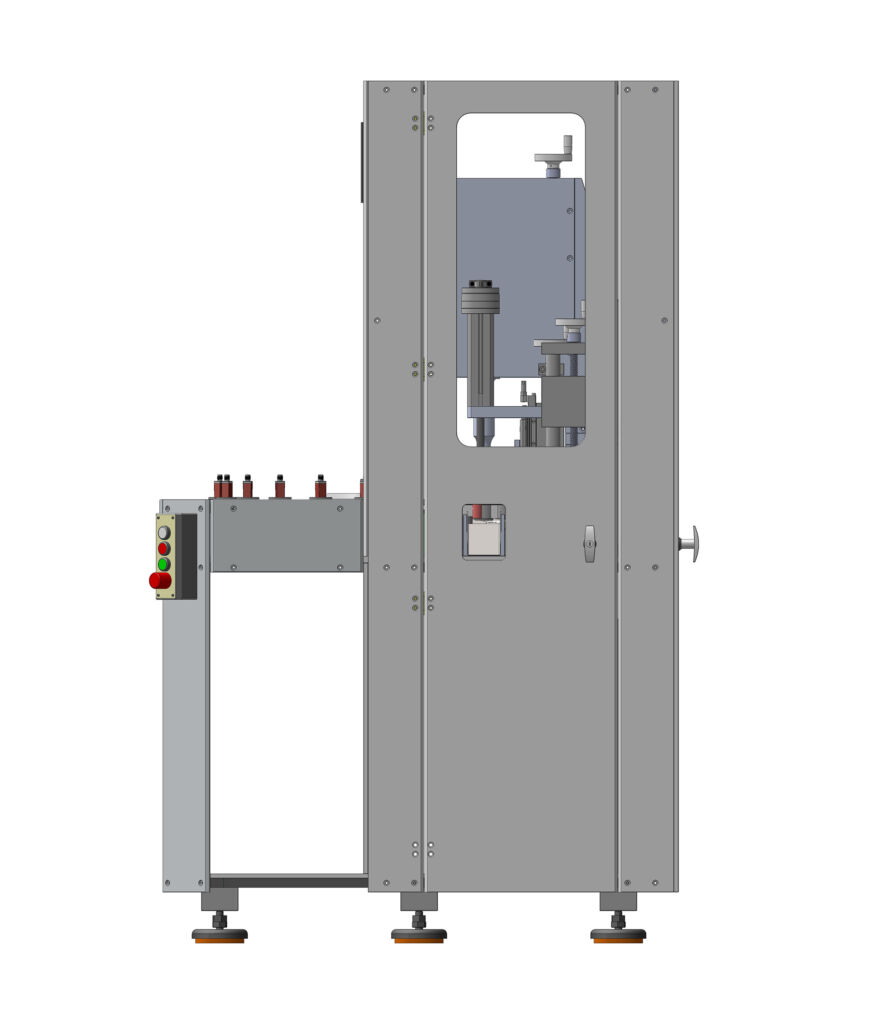

Our ultrasonically welded lid & body assembly machine is a high-tech system that enables fast and strong joining of plastic and similar materials. Thanks to high frequency ultrasonic vibrations, it strongly joins lid and body parts without the use of additional adhesives or additional materials. This technology offers high-strength and hygienic joining solutions, especially in the cosmetic, medical and food packaging sectors.

Fully Automatic Cover & Body Assembly System

Our machine speeds up the production process by automatically aligning and ultrasonically welding the lid and body components together. Thanks to its precise calibration system, it ensures the correct positioning of each part, minimizing the rate of defective production.

- Ultrasonic welding technology: Fast, strong and material-free joining.

- Sensor-assisted quality control: Automatically detects defective parts.

- Fast format change: Easy adaptation to different cover and housing types.

- Energy efficient operation: Minimal energy consumption with highly efficient ultrasonic waves.

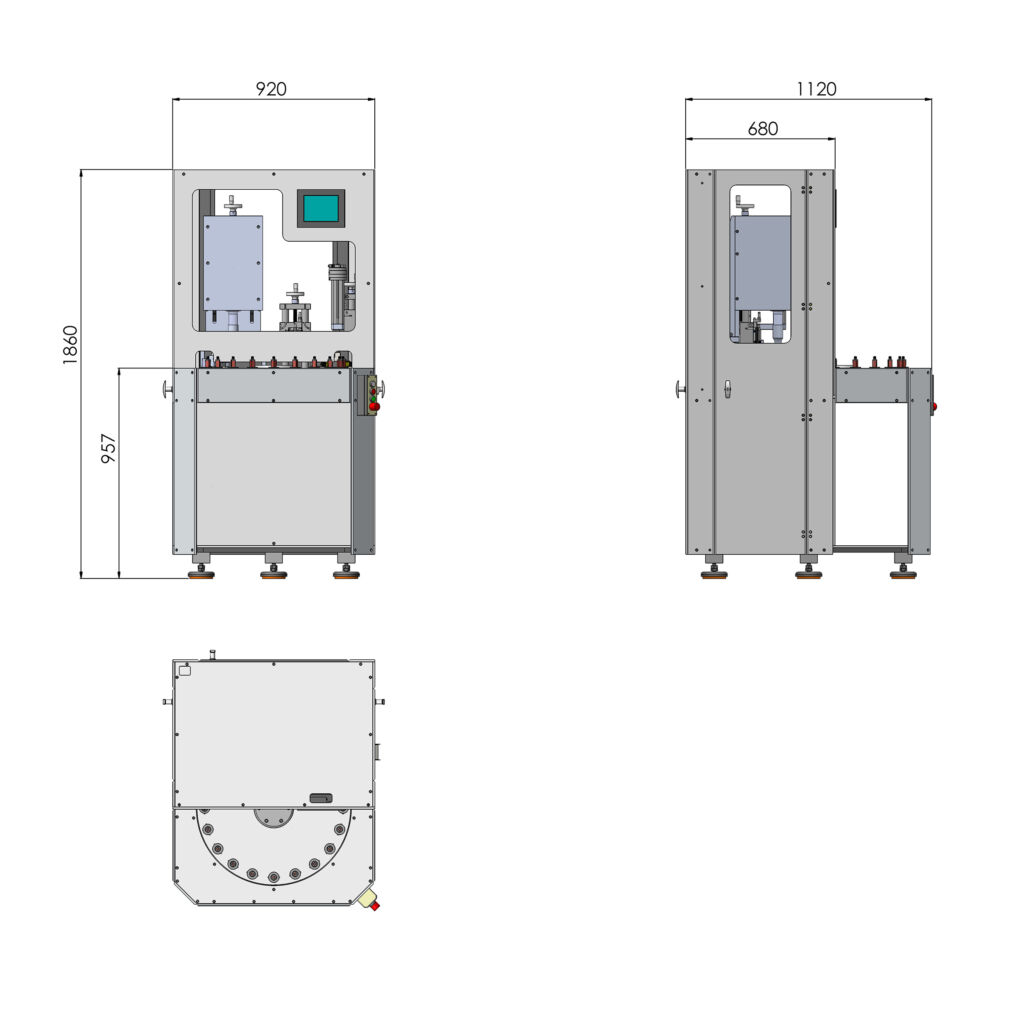

Technical Drawings