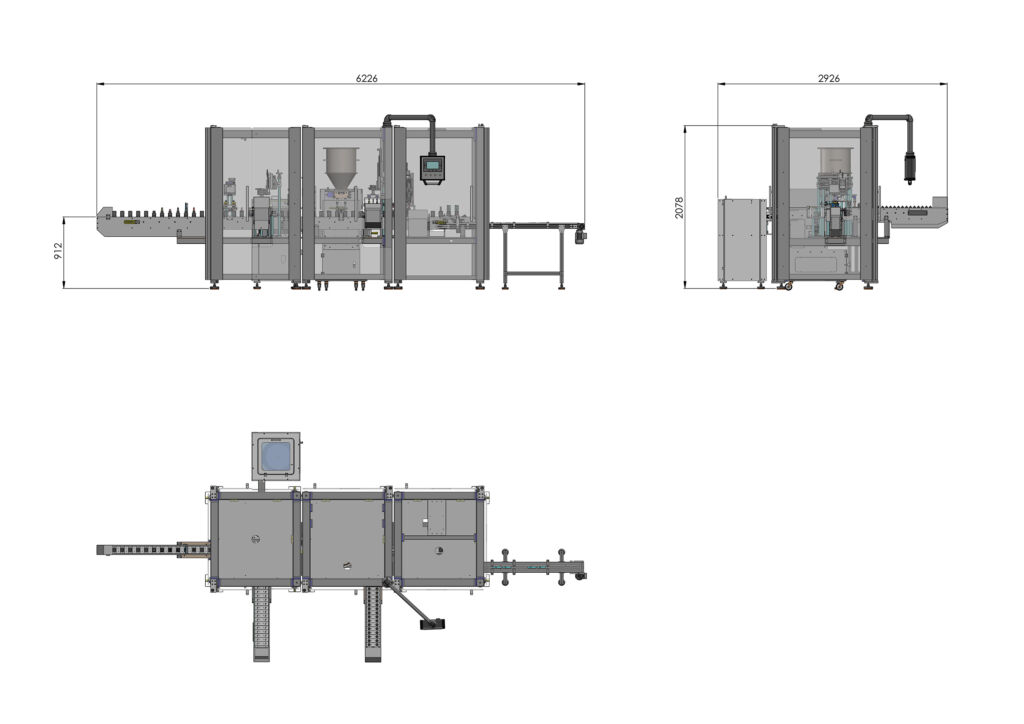

Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Filling Accuracy: | ± 2% |

| Capacity: | 40-45 pcs/min |

| Air Pressure: | 6 Bar |

| Tube Sizes: | Min.Ø15, Max.Ø30 mm |

| Tube Height: | Min.45 mm, Max.100 mm |

Area of Use

This machine is widely used for filling mascara, lipgloss and eyeliner products.

The machine output can be integrated with Labeling, Inkjet or Laser Coding, Sleeve or Boxing Machines.

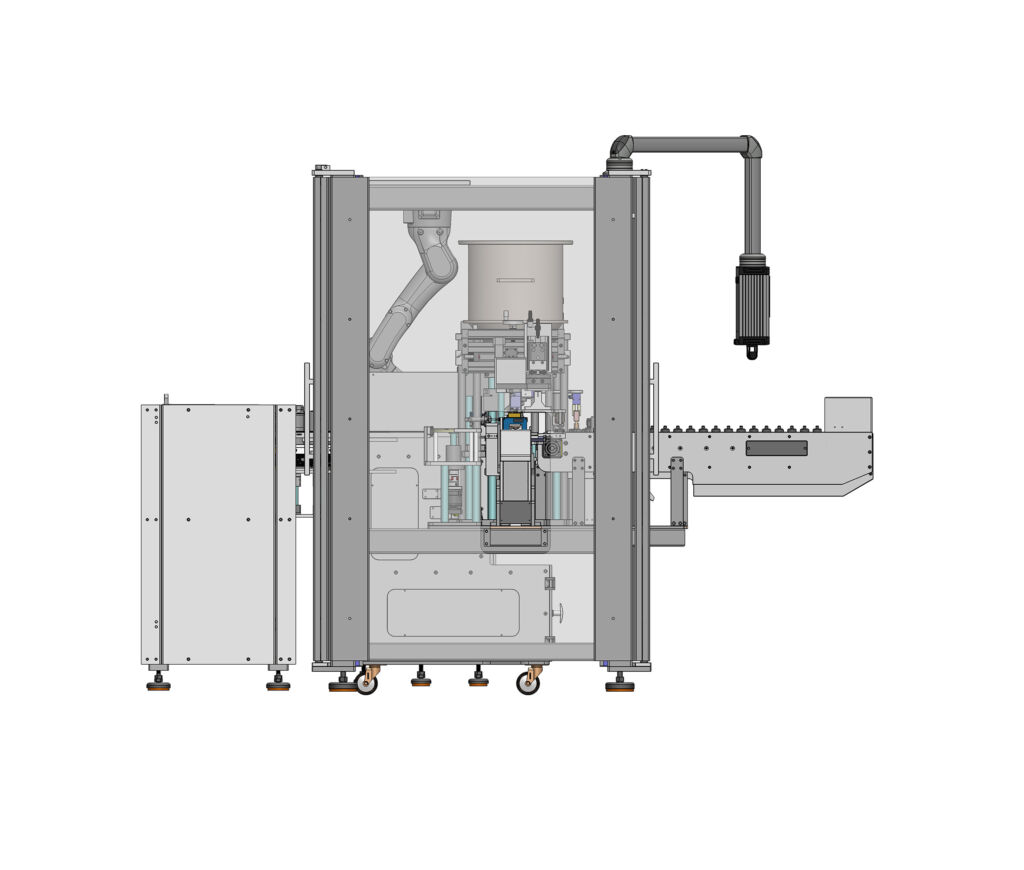

- Modular design, PLC control unit

- 30L boiler capacity made of 316 stainless steel

- Precise filling system with portable filling trolley driven by servo motor. Dual filling nozzles

- Ability to monitor parameters such as torque, speed etc. on the touch screen with servo closing system

- No tubes, no stoppers, no filling thanks to sensors

- Manual stopper stacking conveyor for different types of stoppers

- Easy to change interlocking mold system

Specially designed for high viscosity mascara, eyeliner and lipgloss products, this machine provides operator assisted semi-automatic filling. It offers precise and accurate filling with servo volumetric filling technology and excellent results with automatic labeling module. It is an ideal solution for small and medium-sized producers, offering high productivity at low cost.

Precise filling and flexible production

Our machine has ergonomic stations that minimize operator intervention. Adjustable height platforms and sensor-assisted filling nozzles minimize the margin of error during filling. Manual loading processes are optimized, facilitating the production process and preventing time loss.

Easy interchangeable formats and fast cleaning

The machine has a modular design that can easily adapt to different tube sizes and packaging types. Thanks to its tool-free format changeover feature, production lines can be switched quickly. It is made of food compatible stainless steel and complies with GMP and hygiene standards with its easy-to-clean structure.

- Ergonomic workspace: Operator-friendly design.

- Automatic error detection: Sensor control system prevents incorrect filling.

- Modular structure: Fast cleaning and ease of maintenance.

- Economic and efficient: Ideal for small and medium-sized producers.

- Integrated labeling: Filling and labeling in one operation.

Technical Drawings