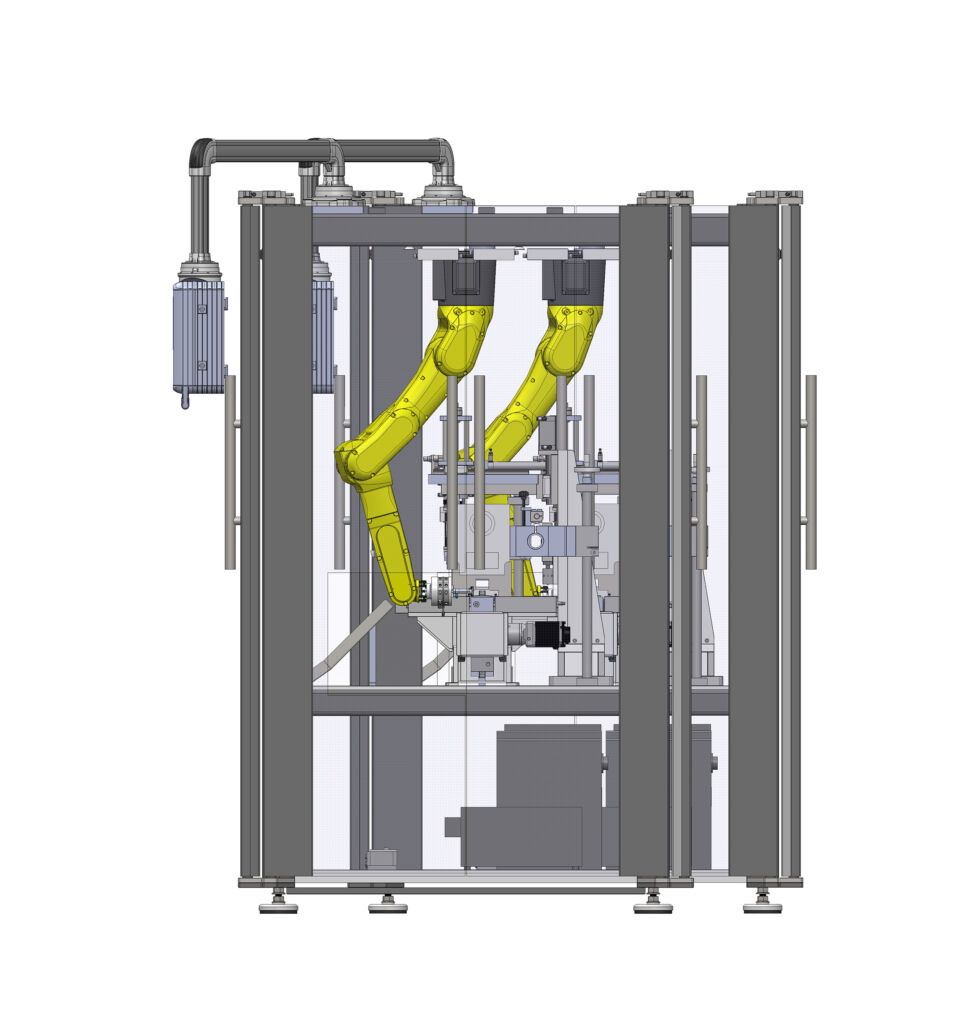

Robotic Double Surface Screen Printing Machine

It is an ideal solution for companies that want to optimize their production processes by screen printing on two different surfaces or two different colors on the same surface. It provides maximum efficiency in production thanks to its high precision, durable structure and automatic feeding system.

Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Capacity: | 20-30 pcs/min |

| Air Pressure: | 6 Bar |

| Product Dimensions: | Min.Ø15, Max.Ø70 mm |

| Product Height: | Min.5 mm, Max.100 mm |

Area of Use

This machine is used for screen printing on two different surfaces of plastic products of various sizes or on the same surface in two different colors.

- Modular design

- PLC control unit

- Product fixing and mold locking with automatic vacum

- Robotic 2nd Edition Product Transfer

- Servo motor driven conveyor systems

- Product availability control system thanks to sensors

- Easy to change mold system

- Automatic product discharge

Robotic Double Surface Screen Printing Machine provides excellent quality by accelerating production processes thanks to its ability to print on two surfaces simultaneously. This system, which works with a high-precision robot arm, is designed to perform the printing processes of tubes, bottles, caps and other cylindrical surface products used especially in the cosmetics, pharmaceutical, food and packaging sectors at the highest level.

Fully Automatic Robot Assisted Screen Printing System

Our machine is an innovative system capable of screen printing on two surfaces simultaneously. Thanks to the robot-assisted feeding mechanism, the products are correctly aligned and the printing process is error-free. The high precision servo motor system guarantees that each print is realized with the same quality standard.

- Simultaneous screen printing on double surface: Provides excellent quality to various packaging products.

- Robot-assisted automatic alignment: Automatically feeds and aligns products.

- Servo motor-controlled printing system: Offers maximum precision and clarity.

- Fast format change: Easy adaptation to products of different diameters and heights.

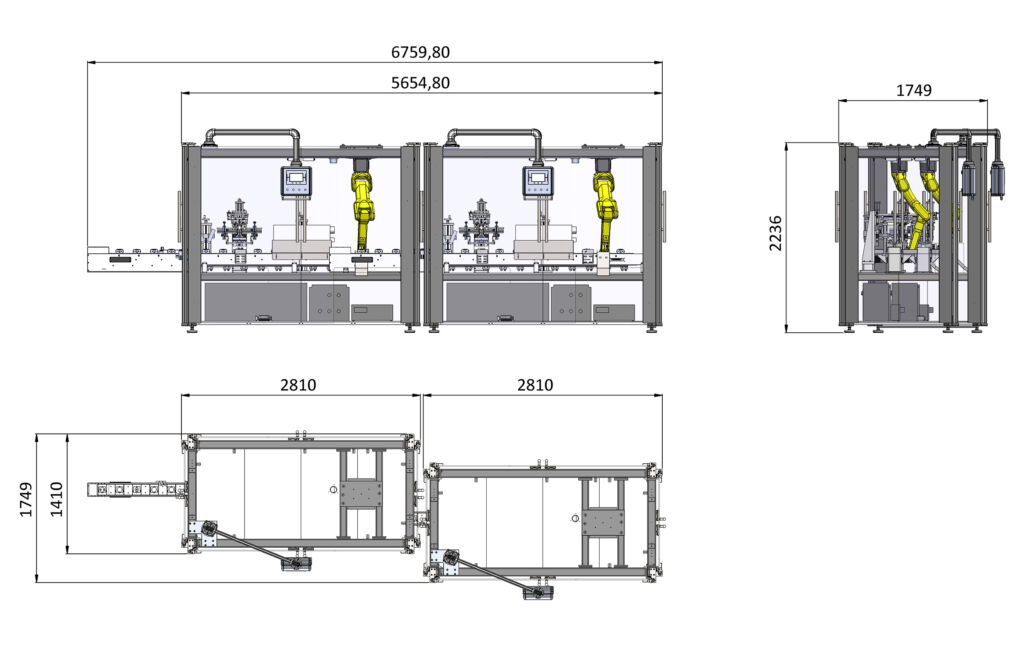

Technical Drawings