Powder Assembly Line

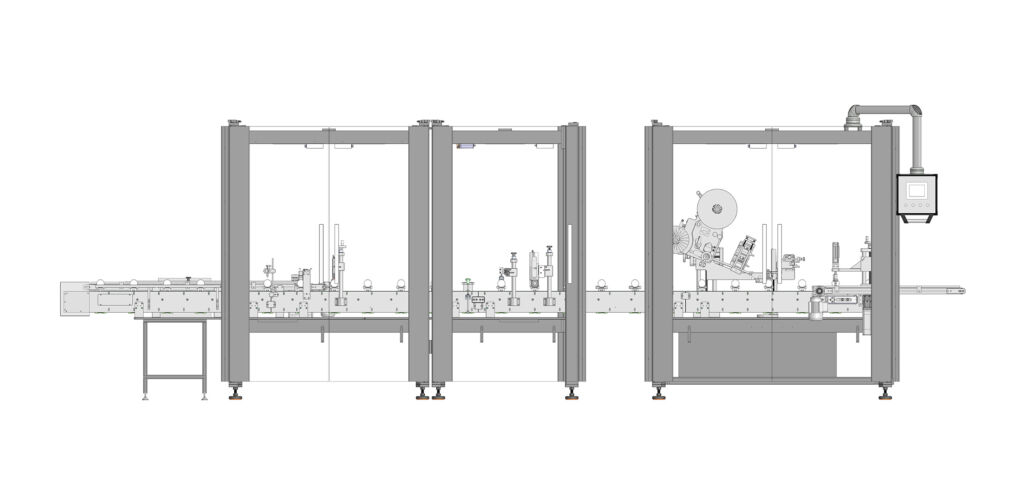

The semi-automatic powder assembly machine is integrated at the end of the powder press printing machine to assemble the products more compactly and quickly into the powder godets packaging, and at the end of the line, together with the labeling machine, the products are ready to be boxed.

Powder

Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Capacity: | 18 pcs/min |

| Air Pressure: | 6 bars |

| Product Dimensions: | Min.Ø30, Max.Ø100 mm |

| Product Height: | Min.8mm, Max.20mm |

Area of Use

This machine is commonly used for the assembly of products such as powder and blush.

- Modular design, PLC control unit

- Precise positioning with servo motor-driven conveyor system

- Ability to use only as labeling machine or only as assembly machine by turning off the necessary stations from the screen

- Ability to work independently from the powder press machine

- Easy to change interlocking mold system

Our powder assembly line is designed to speed up and automate the mass production processes of compact powders in the cosmetics industry. It offers high quality and consistency in production by ensuring that the fitting, pressing and assembly of powder caps is carried out without errors.

Fully Automatic Powder Assembly System

Our machine enables automatic alignment and assembly of the lid, mirror lid and internal components of compact compact powders. The sensor-assisted system guarantees the correct positioning of each part and a flawless assembly process.

High Precision Sensor Controlled Operation

Advanced sensors automatically align and assemble powder lids, lower cases and interior compartments.

- Fully automatic assembly system: Assembles the powder components faultlessly.

- Quick format change: Easy to adapt to different designs and sizes.

- PLC control panel with touch screen: User-friendly interface.

- Stainless steel body: Hygienic and durable.

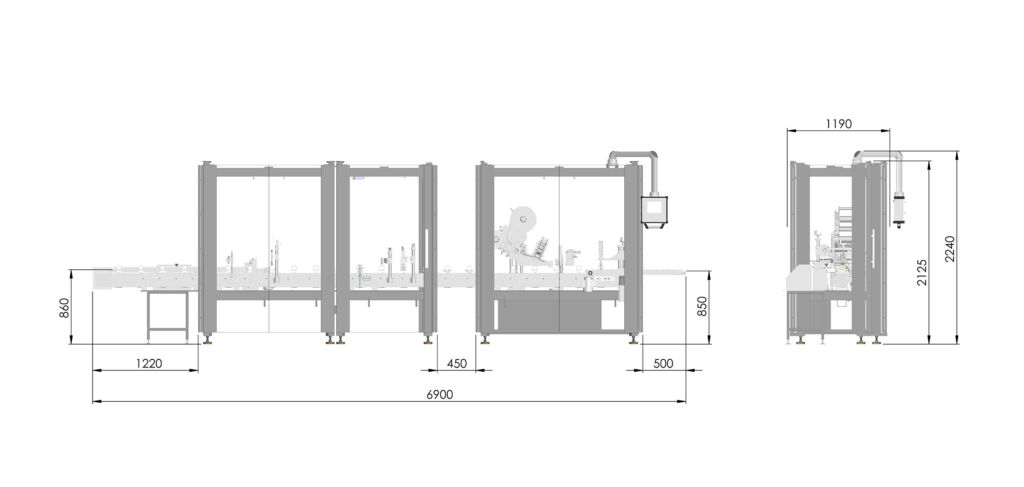

Technical Drawings