Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Filling Accuracy: | ± 2% |

| Capacity: | 40-45 pcs/min |

| Air Pressure: | 6 Bar |

| Tube Sizes: | Min.Ø8, Max.Ø20 mm |

| Tube Height: | Min.30 mm, Max.65 mm |

Area of Use

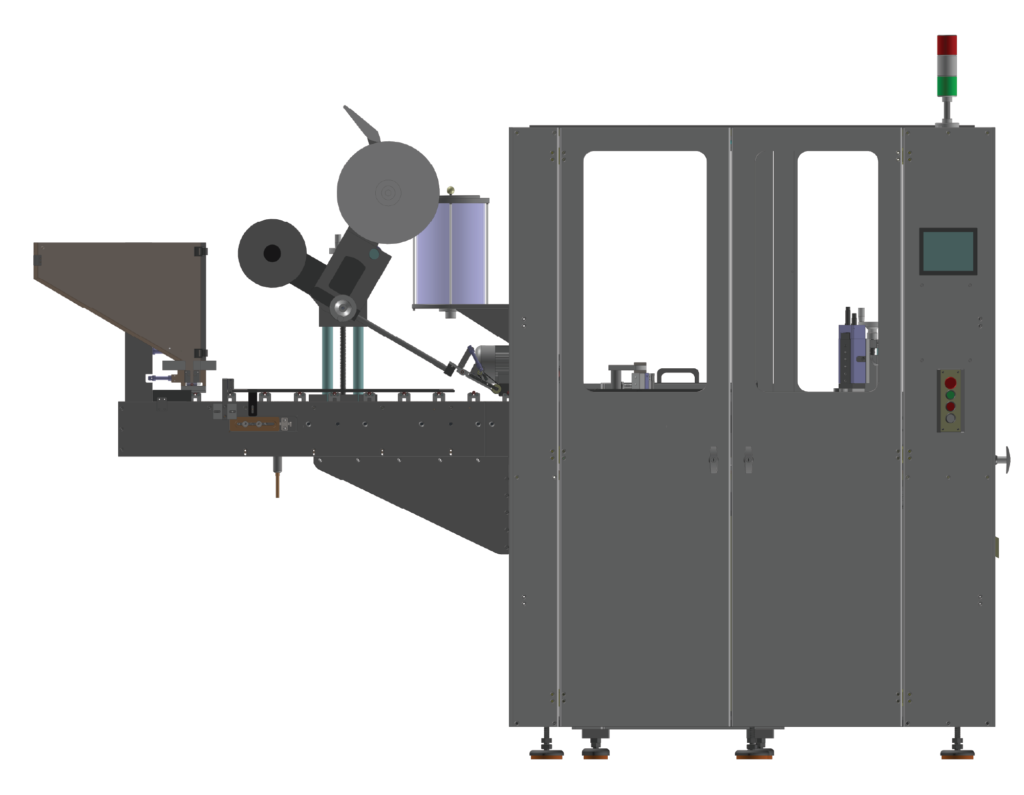

This machine is widely used for filling and labeling tester bottle products.

- Modular design, PLC control unit

- 316 stainless steel filling nozzle

- Precise filling system driven by servo motor

- Fast and precise labeling with Herma labeling module

- Ability to monitor parameters on the touch screen

- No tubes, no stoppers, no filling thanks to sensors

- Manual stopper stacking conveyor for different size bottles

- Easy to change mold system

Our mini perfume tester filling and labeling machine offers a compact and flexible production process with a high precision servo volumetric filling system. Designed for mass production of small volume tester perfume bottles, it provides high speed and accuracy filling. Integrated with the labeling module, this system increases quality and production capacity.

Fully Automatic Filling and Labeling System

This machine performs automatic feeding, filling, capping and labeling of small-sized perfume tester bottles in a single system. High-precision filling nozzles ensure that each bottle is filled with the same amount of perfume and sensor-controlled systems ensure an error-free production process.

Advanced Sensor Controlled Operation

Sensör destekli sistemler sayesinde tüp, tıpa ve dolum kontrolü sürekli yapılır. Dolum sırasında hatalı şişeler tespit edilerek otomatik olarak sistemden ayrılır. Bu sayede her üretim partisi yüksek kalite standartlarını karşılar.

- Servo volumetric filling system: Filling with ±4% accuracy.

- Sensor-supported error detection: Prevents incomplete or incorrect filling.

- Herma labeling module: High speed precision labeling.

- Fully integrated production line: Filling, capping and labeling in one system.

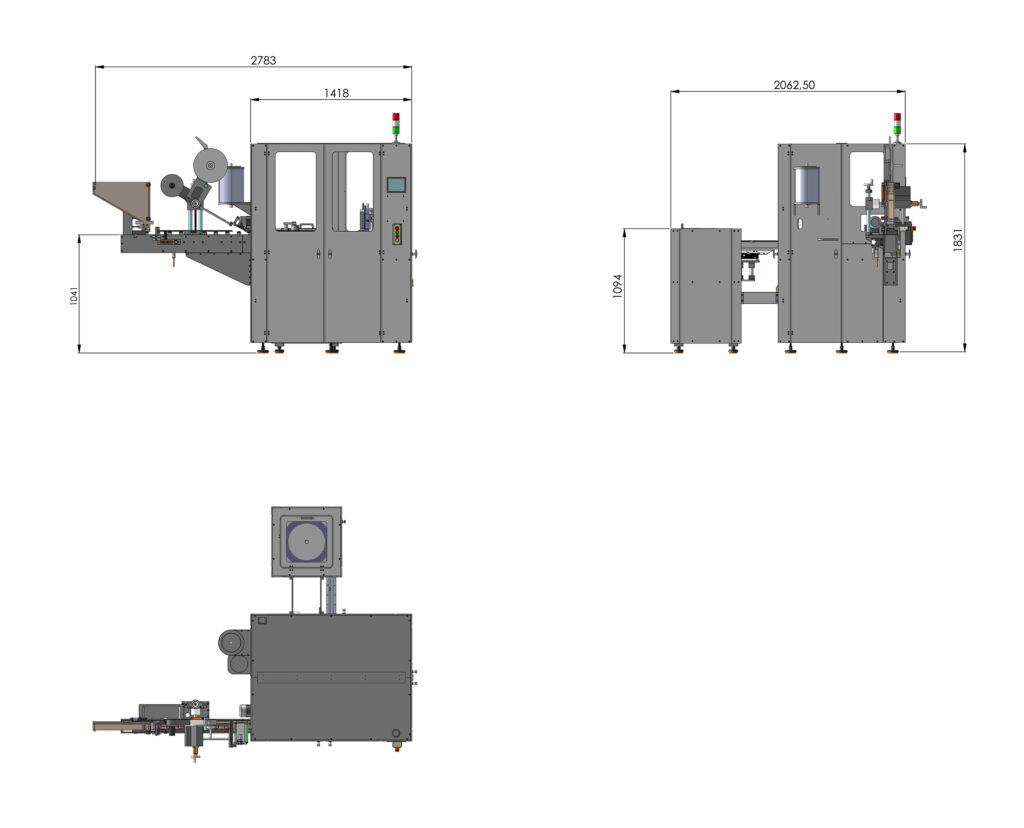

Technical Drawings