Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Print Sensitivity: | 0.1mm |

| Capacity: | 22-30 pcs/min |

| Air Pressure: | 6 Bar |

| Working System: | Pneumatics |

Area of Use

This machine is widely used for pad printing on products.

- PLC control unit

- Single color printing with 120mm diameter closed dye chambers

- The plates on which the plates are placed are movable in XY axes and bearings that provide ±10° rotation of its own axis

- Suitable for cylindrical product printing

- Adjustable product placement apparatus in X-Y-Z axis

- No extra maintenance thanks to maintenance-free type elements

- Hopper and buffer group move with different cylinders and separate speed adjustment

- Up to 50% Ink Savings with closed chamber ink system

- Maintenance-free pneumatic equipment

The Manual Pad Printing Machine is a compact system designed for low and medium scale production, capable of making high quality prints on small products. Suitable for plastic, metal, glass and other surfaces, this machine offers an economical and easy-to-use printing solution.

Precision Printing with Manual Control

Our machine works with a manual printing system, enabling high precision printing under operator control. It is an ideal solution especially for special designs and small production series. Thanks to its easy-to-use structure, it allows operators to print efficiently in a short time.

Compact and Durable Design

Manuel tampon baskı makinemiz, az yer kaplayan ergonomik bir tasarıma sahiptir. Hafif yapısı sayesinde kolay taşınabilir ve farklı üretim alanlarına entegre edilebilir.

- Manually controlled printing: Provides user-friendly and flexible production.

- Precise print quality: Excellent results on small and detailed graphics.

- Compact and portable design: Ergonomic design with a small footprint.

- Quick format change: Easy adaptation to different surface types.

- Low energy consumption: Manual operating mechanism that does not require electricity.

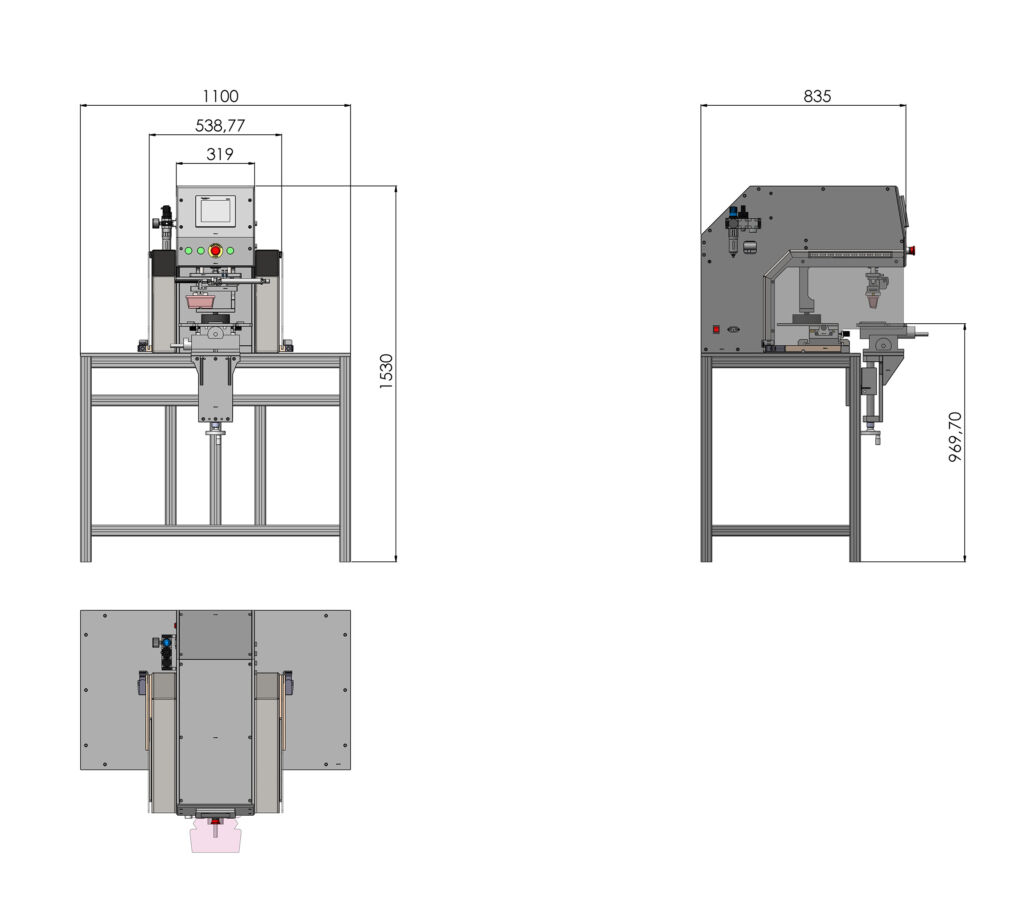

Technical Drawings