Technical Parameters

| Filling Accuracy: | ±3% |

| Capacity: | 25-30 pcs/min |

| Air Pressure: | 6 Bar |

| Working System: | Pneumatics (Except for agitator and heated hopper systems) |

| Boiler Capacity: | 10 kg (316 stainless) |

| Fill Range: | 30ml-300 ml |

| Operating Temperature | 20-90 degrees |

| Number of Filling Cylinders: | 1 piece |

Area of Use

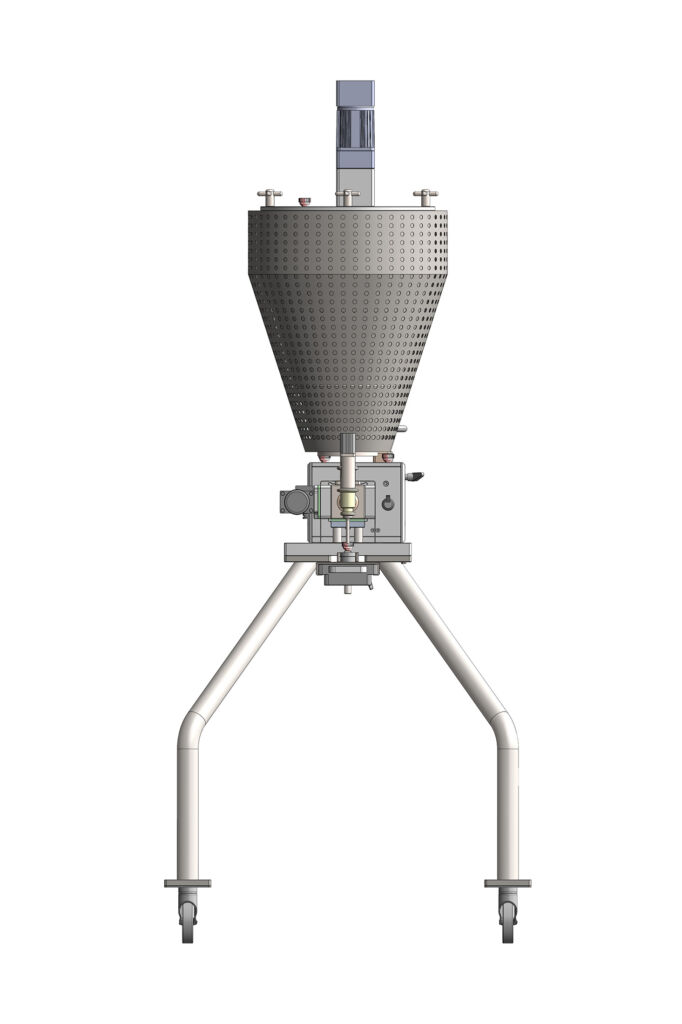

This machine is widely designed for creams, gels, lotions and products that require hot filling.

- The machine is a volumetric filling machine working with pneumatic system.

- It takes the product from a 10 lt boiler with standard or level system control according to the need.

- The weight is easily adjusted and recorded with the dial lever and numerator.

- Sealing elements are made of teflon, viton or polyethylene according to the chemical properties and temperature of the material to be filled.

- The parts on the machine are connected to each other with tri-clamps (clamps). Nozzle, valve and filling piston are designed for easy cleaning. It can be easily disassembled without any tools.

- Depending on the product, liquid, viscous or granular interchangeable filling nozzles are available.

- There is a platform with a drawer to put the packages on during the filling process; this platform can be easily adjusted up and down according to the size of the package.

- Thanks to its wheels, it can be made ready for filling easily and quickly at the desired location.

- Table top and wheeled models are available.

Our manual heated filling machine is especially designed for wax-based products, creams, gels, lotions and other products that require hot filling. Widely used in the food, cosmetics and pharmaceutical industries, this machine stands out with its user-friendly structure and precise filling system.

Excellent Fluidity with Heated Filling Technology

Thanks to the heated hopper and filling nozzles in our machine, products with high viscosity or requiring hot filling are kept at the ideal temperature and filled fluidly. This ensures homogeneous filling of products and more controlled production processes.

Easy Operation and Fast Format Change

The machine is easily adaptable to different bottle sizes and filling volumes. Thanks to its manual operation mechanism, it is an ideal solution for small-scale production or R&D laboratories. It offers high performance with quick-change filling nozzles and in-chamber mixing option.

- Heated filling system: Provides optimum fluidity for high viscosity products.

- Adjustable temperature control: Temperature levels to suit different product requirements.

- Manual operation: Suitable for small and medium-sized productions.

- Easy to clean bowl and nozzles.

- Stainless steel body: Hygienic and durable design.

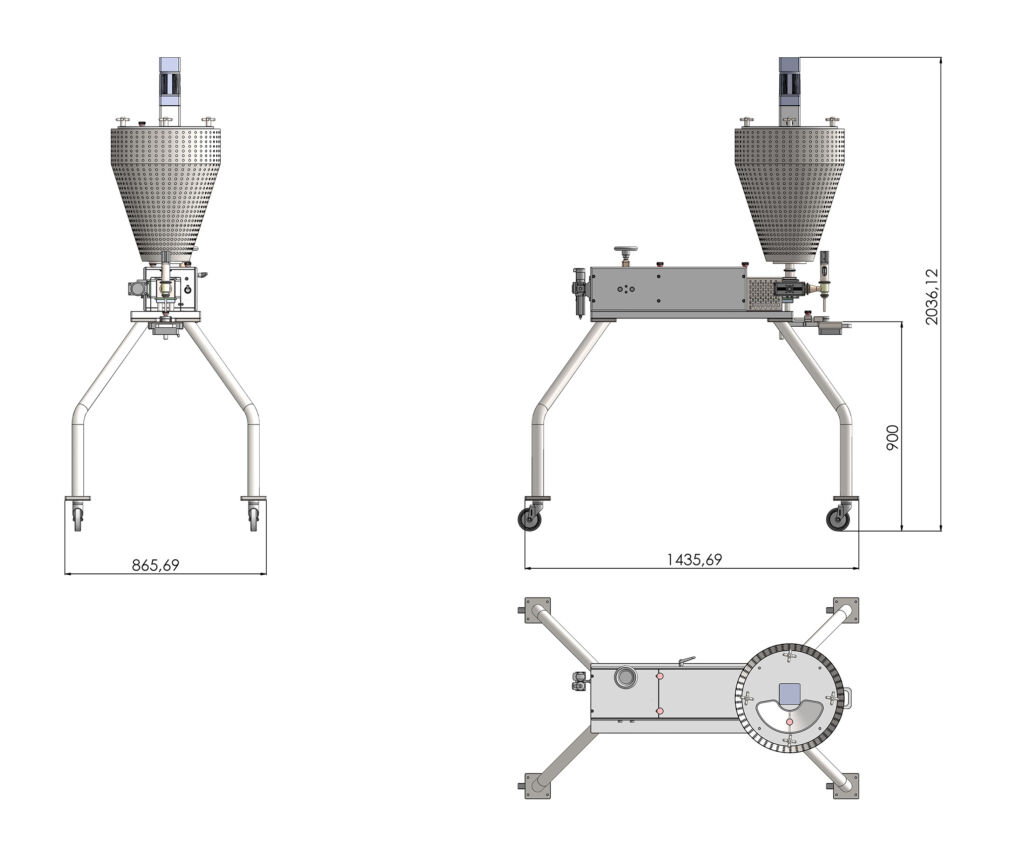

Technical Drawings