Fully Automatic Mascara & Lipgloss Filling Line

Filling with high speed and precision,

Weighing to measure the accuracy of filled products,

Bottom label or body label on the product,

Inkjet or laser coding on the product,

It is a complete line that allows body sleeve or local sleeve on the product.

After the necessary components are loaded into the machine, it offers the opportunity to receive the finished product sleeved from the end of the line untouched.

Mascara

Lipgloss

Eyeliner

Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Filling Accuracy: | ± 2% |

| Capacity: | 55-60 pcs/min |

| Air Pressure: | 6 Bar |

| Tube Sizes: | Min.Ø15, Max.Ø30 mm |

| Tube Height: | Min.45 mm, Max.100 mm |

Kullanım Alanı

This machine is widely used for filling mascara, lipgloss and eyeliner products.

- Modular design, PLC control unit

- 30L boiler capacity made of 316 stainless steel

- Servo motor driven precision filling system with portable filling trolley

- Fully automatic tube, stopper and cap stacking

- Ability to monitor parameters such as torque, speed etc. on the touch screen with servo closing system

- No tube, no stopper, no filling information thanks to sensors

- Fully automated line integrated with Labeling, Inkjet or Laser Coding and Sleeve sections

- Easy to change interlocking mold system

- On-line precision weighing

Our machine is designed to meet the highest quality and productivity standards in the cosmetics industry. It enables precise filling and capping of low and high viscosity products such as mascara, eyeliner and lipgloss into tubes using a servo volumetric filling system. Thanks to its superior technology, it optimizes processes with automatic and semi-automatic production options and offers high accuracy and quality production. Our machine optimizes costs by providing maximum efficiency and minimum error rate in production processes.

Innovative mascara & lipgloss filling system for mass production

The filling process is carried out using servo volumetric systems with precise measurement. The product is sucked from the hopper and carefully filled into the tubes with the help of a rotary slide and filling nozzle. The filled tubes are automatically fitted with brush caps and closed by torque-controlled tightening. Thanks to integrated sensors, the system detects whether there is a tube or not, preventing incorrect filling and increasing production efficiency.

Thanks to the flexible production structure of our machine, fast adaptation to different tube sizes and cap types is ensured. The fast format change feature minimizes time loss in the production line. This is a great advantage for businesses that produce multi-format production.

Semi-automatic or fully automatic option for batch production to suit your needs

Automatic and semi-automatic production options offer businesses flexibility according to different needs. The high precision servo volumetric filling system ensures that each product is filled to the same quality standard. It also keeps hygiene standards at the highest level with its stainless steel body and food compatible materials.

- High precision filling: Accurate and consistent filling process.

- Fully automatic system: Speed up the production process, increase efficiency.

- Fast format change: Easy adaptation to different tubes and caps.

- Operator-friendly design : Easy operation with touch screen.

- Hygienic production: Stainless steel housing and food compatible components.

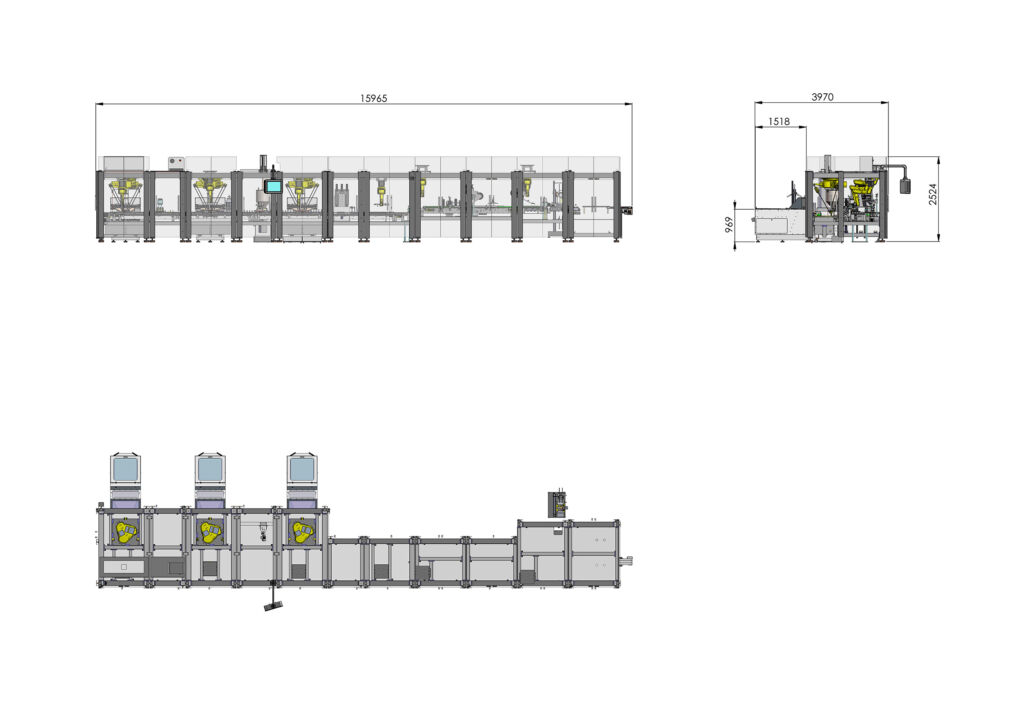

Technical Drawings