Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Print Sensitivity: | ± 0.1g |

| Capacity: | 30-40 pcs/min |

| Air Pressure: | 6 Bar |

| Product Dimensions: | Min.Ø15, Max.Ø70 mm |

| Product Height: | Min.5 mm, Max.100 mm |

Area of Use

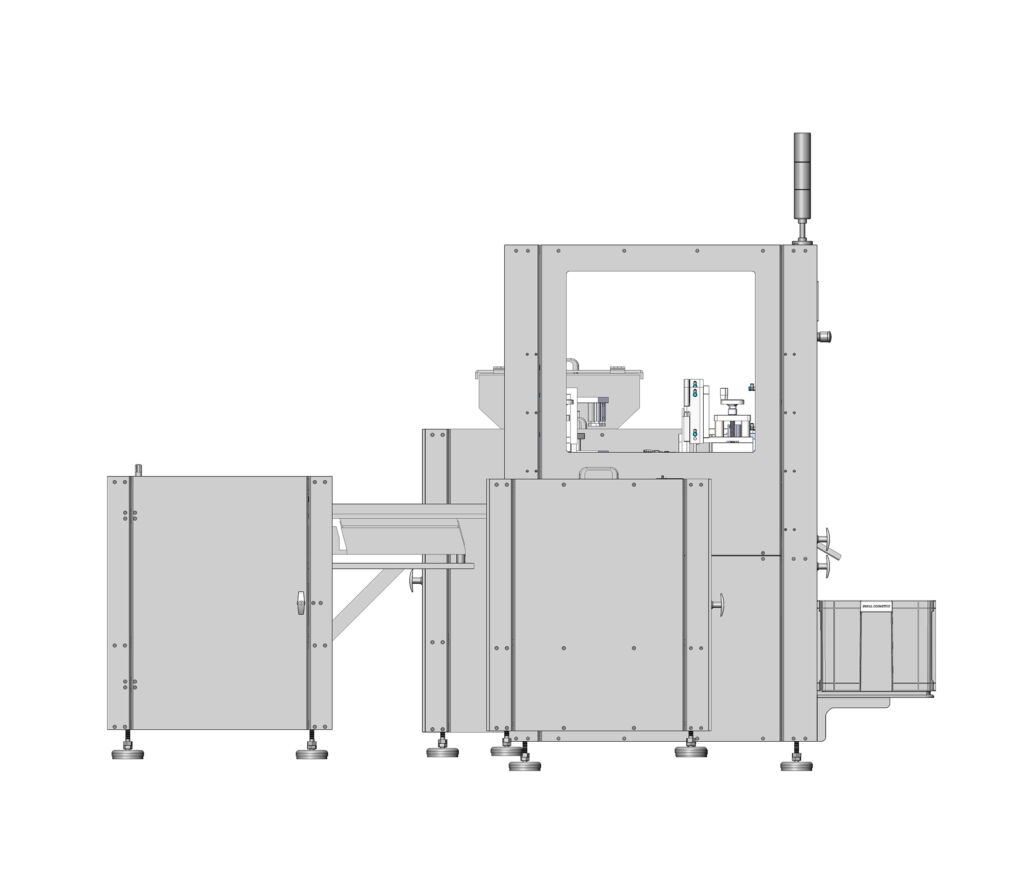

This machine automatically assembles handles, nuts and caps of cosmetic products of various sizes.

- Modular design

- PLC control unit

- Automatic product feeding system

- Product availability control system thanks to sensors

- Easy to change mold system

- Automatic product discharge

Our fully automatic mascara & lipgloss brush and cap assembly machine is an innovative system that automates high precision assembly processes. It enables mascara and lipgloss caps to be assembled with a brush or applicator, offering speed and efficiency in production lines.

Fully Automatic Brush and Cover Assembly System

Our machine speeds up the production process by automatically aligning and assembling product components. Thanks to the sensor-controlled system, each brush and cover is correctly positioned and assembled.

Precise Sensor Controlled Operation

Advanced sensor systems are used for the alignment of products, the correct joining of caps and brushes, and error-free assembly.

- Fully automatic assembly system: Ensures precise and error-free assembly of covers and brushes.

- Fast format change: Easy adaptation to different brush and cap types.

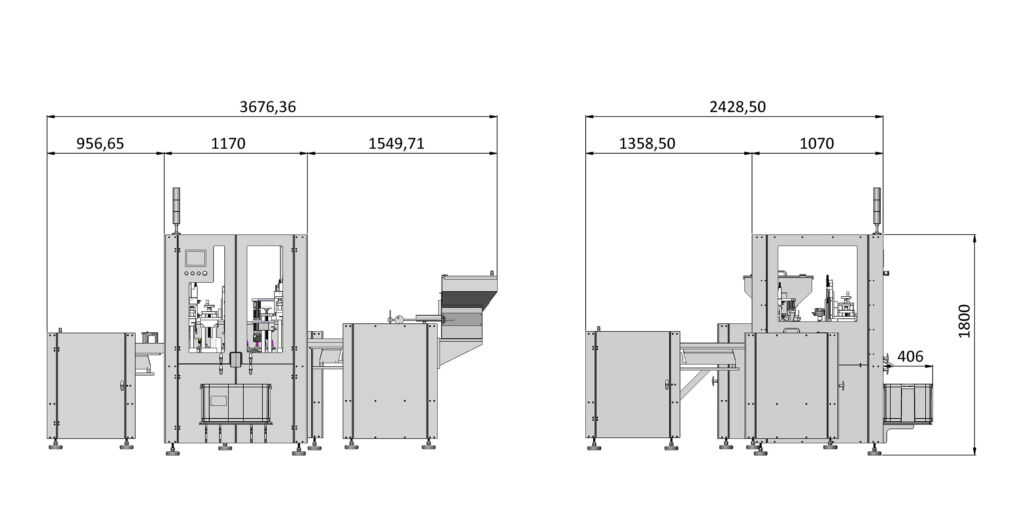

Technical Drawings