Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Print Sensitivity: | 0.1mm |

| Capacity: | 22-30 pcs/min |

| Air Pressure: | 6 Bar |

Area of Use

This machine is widely used for pad printing on products.

- Modular design, PLC control unit

- Automatic product feeding unit designed according to the product

- 1- 4 color printing with 120mm diameter closed dye chambers

- Product carrying apparatus that can be easily changed according to the product

- Printing of two or more materials at the same time

- Two or four prints in a row with high precision

- The plates on which the plates are placed are movable in XY axes and bearings that provide ±10° rotation of its own axis

- Automatic bumper cleaning apparatus

- Pre-treatment before printing with Corona or flame methods

- Automatic feeding and unloading of parts to be printed

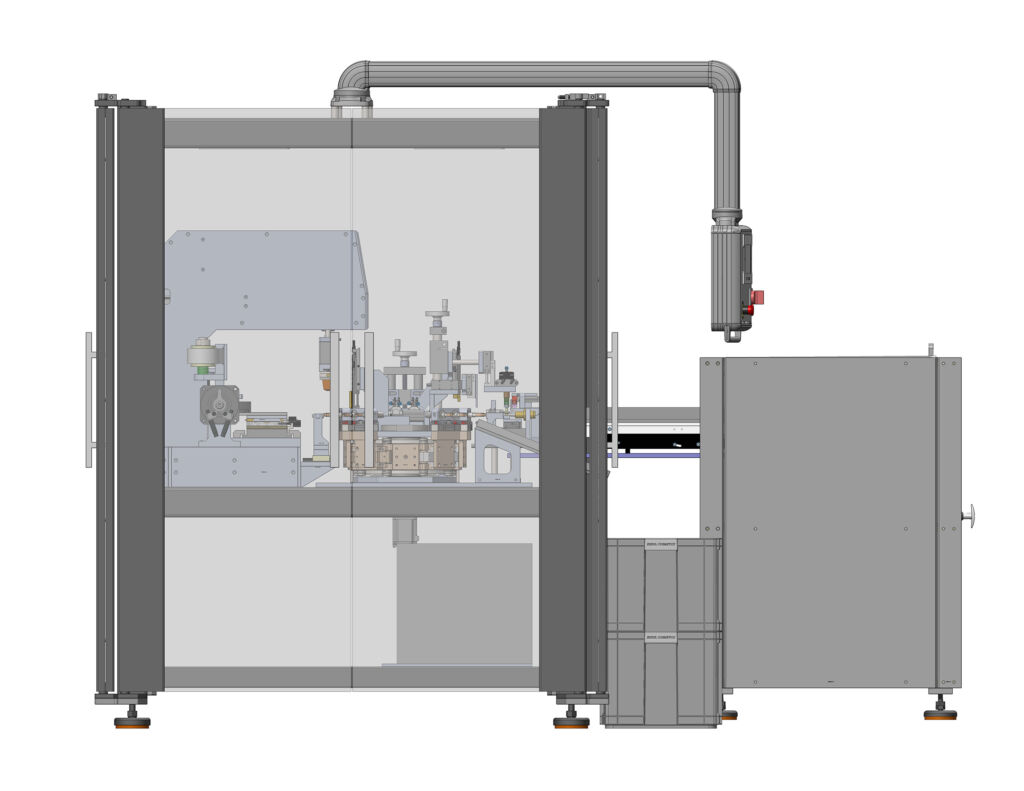

Fully Automatic 4 Surface Pad Printing Machine is an advanced system that can simultaneously pad print on four surfaces on cans, bottles, caps and various packaging products. Ideal for cosmetic, food, pharmaceutical and industrial packaging, this machine offers high resolution and durable prints.

Fully Automatic 4 Surface Printing System

This machine is capable of printing on four different surfaces of the products at the same time. Thanks to the high precision servo motor controlled print heads, the print is applied perfectly on every surface. It offers uninterrupted and error-free printing with its automatic product feeding and alignment system.

Flexible Production and Ease of Format Change

- Simultaneous printing on 4 substrates: The ideal solution for boxes, lids and bottles.

- Servo motor controlled printing system: Provides maximum precision and clarity.

- Quick format change: Easy adaptation to different product types and sizes.

- PLC control panel: Easy operation with user-friendly interface.

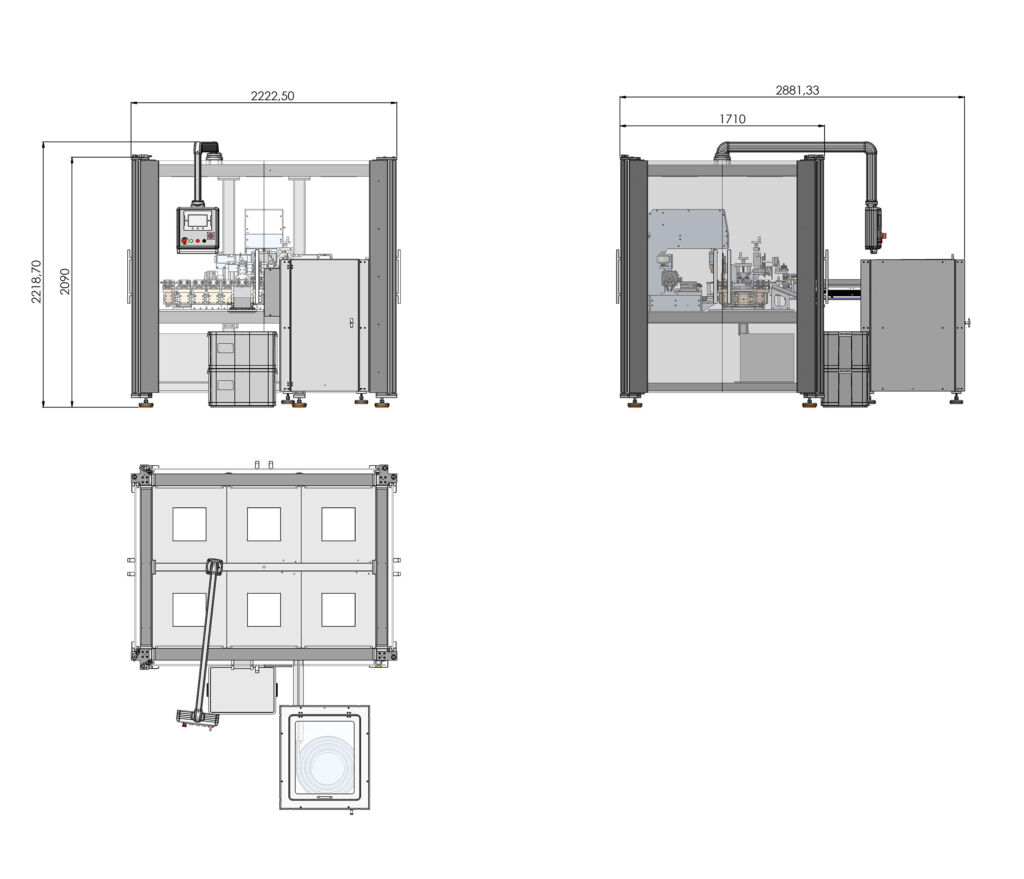

Technical Drawings