Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Filling Accuracy: | ± 3% |

| Capacity: | 35-45 pcs/min |

| Air Pressure: | 6 Bar |

| Fill Range: | 10 ml - 200 ml |

Area of Use

This machine is widely used for filling foundation.

Inkjet coding can be integrated to write expiration date, batch no, barcode, LOT number on the bottles.

- Modular design, PLC control unit

- 30L boiler capacity made of 316 stainless steel

- Precise filling system with portable filling trolley driven by servo motor. Dual filling nozzles

- Dual filling nozzles.

- Ability to monitor parameters such as torque, speed etc. on the touch screen with servo closing system

- Additional cap nailing station for click caps

- Manual bottle and cap stacking conveyor for different types of bottles and caps

- Easy to change interlocking mold system

- Easily adjustable high filling range thanks to interchangeable filling chambers

Our foundation filling machine is designed for precise and fast filling of high viscosity products in the cosmetics industry. Specially developed for liquid and cream form foundations, this system maintains high quality standards by ensuring hygienic production processes at the highest level.

Advanced Servo Volumetric Filling Technology

Our machine is equipped with a servo motor assisted volumetric filling system, ensuring that each filling is carried out with precision. By using special filling nozzles according to the structure of the product, air bubbles are prevented and a homogeneous distribution is ensured.

Thanks to advanced sensor systems, bottles, caps and the filling process are continuously controlled. Incorrect or incomplete fillings are immediately detected and removed from the production process. This ensures maximum quality and efficiency.

- Quick changeable molds: Easy adaptation to different bottles and tubes.

- Fully automatic lid closing system: Lids are precisely positioned and tightened.

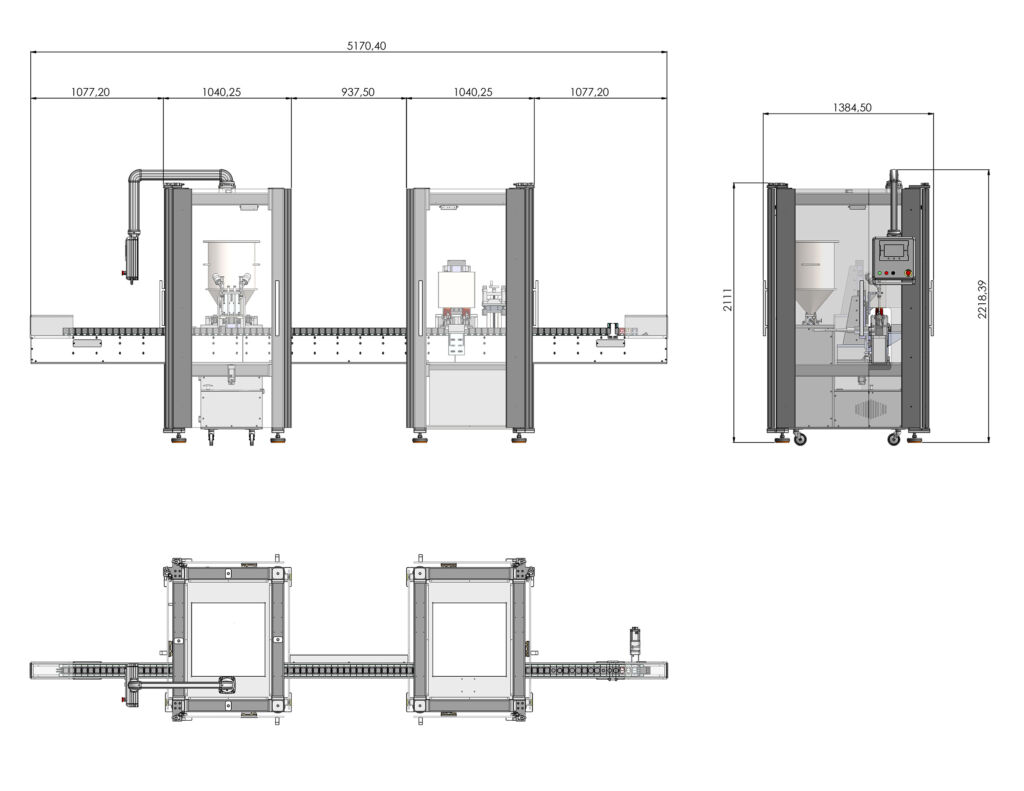

Technical Drawings