Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Print Sensitivity: | ± 1mm |

| Capacity: | Up to 120pcs/min (May vary according to package diameter and label length.) |

| Module Speed: | 6 Bar |

| Tag Height: | Min.20mm, Max.240 mm |

| Product Dimensions: | Min.Ø20 mm, Max.Ø100 mm |

Area of Use

This machine is widely used for labeling cosmetic, chemical and food products.

It can be integrated with inlet and outlet filling, packaging machines.

- Advanced easy-to-use PLC control unit

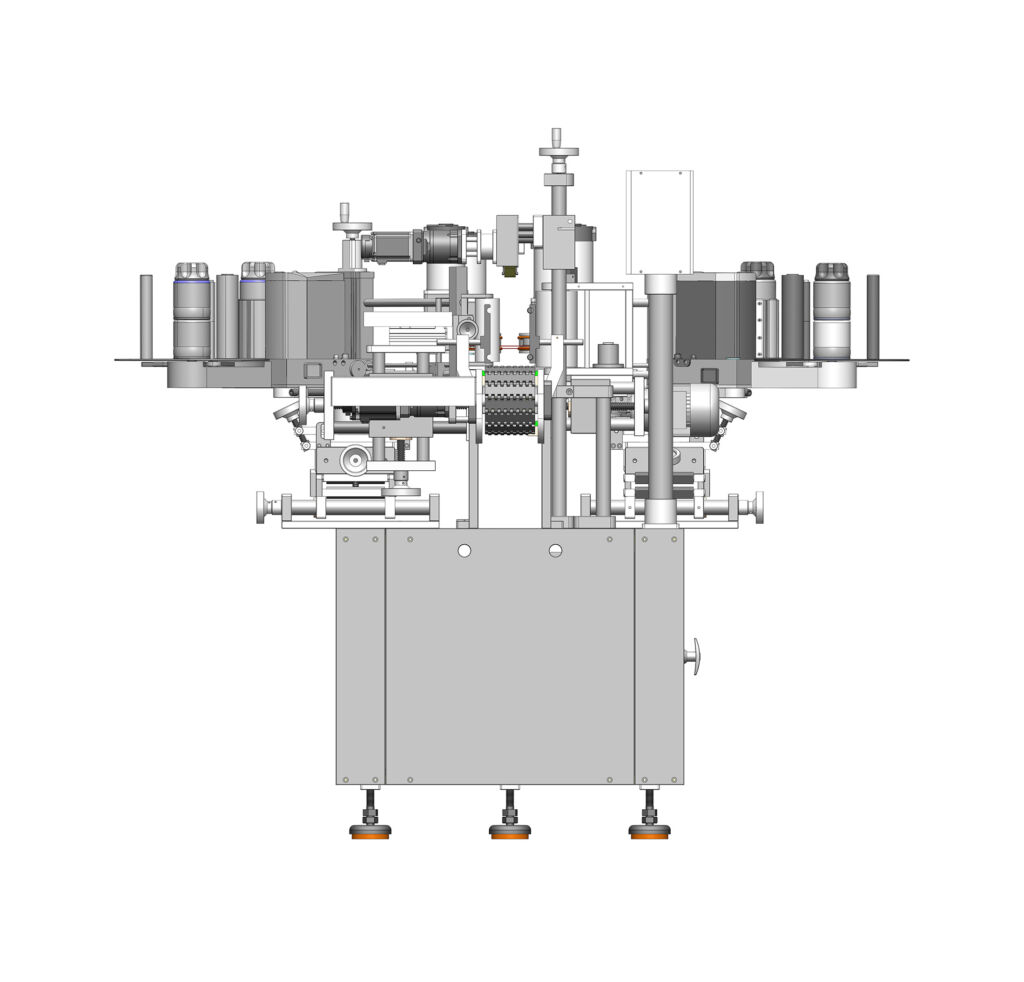

- Aluminum anodized chassis, touch operator panel, Herma module

- High precision speed adjustment thanks to upper and lower conveyors driven by servo motors

- High-level labeling thanks to independent sorting and correction stations

- Max. adjustment possibility with X-Y-Z axis and degree adjustable labeling module

- Ability to control input, output and all operations thanks to sensors, reporting

- Wide product range with cylinder surface labeling module

- Easy product changeover, high speed rewinding

Our double-sided and round surface labeling machine is designed to apply labels with high precision to a variety of packaging such as bottles, jars and tubes used in the cosmetic, food, pharmaceutical and chemical industries. Suitable for both flat and round surfaces, this system ensures high speed and efficiency in production lines with its fully automatic operation.

Versatile Use for Double-Sided and Round Products

Our machine is compatible with a wide range of products thanks to its ability to label double-sided and round surfaces simultaneously or separately. It has a PLC control system and all operations can be easily managed via touch screen.

- Double-sided and round surface labeling: Compatible with various packaging types.

- High speed labeling: Suitable for mass production with 80-100 pcs/min capacity.

- PLC control panel with touch screen:Easy operation and fast adjustment.

- Durable stainless steel body: Hygienic and long-lasting use.

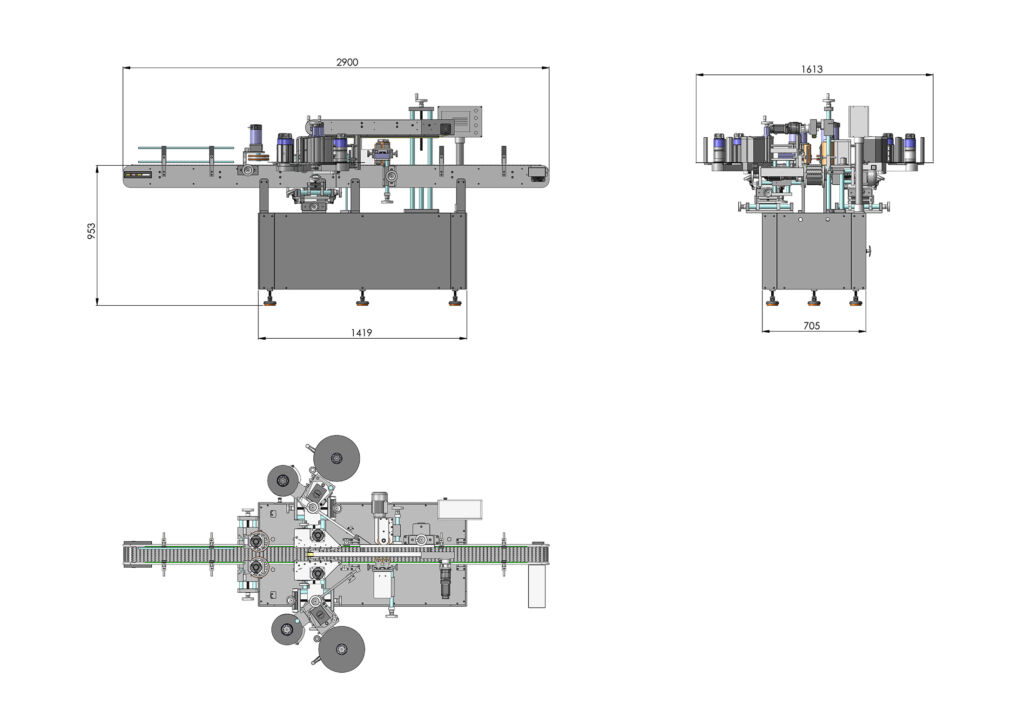

Technical Drawings