Horizontal Sleeve Machine

This machine is widely used in the cosmetics industry.

Especially for products with thin and difficult to stand packaging such as Lipstick, Mascara, Lipgloss, Eyeliner, Eyeliner, Lip Liner, Eye Liner, etc., it allows the outer parts of the products to be tightly wrapped with a full body or locally transparent protective film.

Mascara

Lipgloss

Eyeliner

Liner

Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Capacity: | 60-120 pcs/min |

| Air Pressure: | 6 Bar |

| Product Dimensions: | Min.Ø8, Max.Ø30mm |

| Product Size: | Min.50 mm, Max.150 mm |

Area of Use

This machine performs the process of sleeve wrapping of cosmetic product packages of various shapes and sizes semi-automatically or fully automatically by integrating with a line.

- Modular design

- PLC control unit

- Integrated product feeding system with semi-automatic or fully automatic systems

- Product availability control system thanks to sensors

- Easy to change mold system

- Automatic product discharge

Our horizontal sleeving machine is designed for sleeving packaging of cosmetics and personal care products in various sizes. It strengthens the brand identity by ensuring that the products are covered with an aesthetic and durable packaging. Equipped with a PLC control unit, it offers error-free and highly efficient production thanks to its sensor-supported systems.

Precise and Fast Sleeve Packaging Solution

Our machine speeds up the production process by performing sleeve coating processes semi-automatically or fully automatically. Thanks to its modular structure, it can be easily adapted to different product sizes. The high precision cutting and application mechanism ensures perfect sleeve coating.

- Prevents contamination and damage to the product.

- It improves product appearance and displays brand and product information.

- Increases product shelf life by providing a barrier against moisture, dust and other contaminants.

- Flexibility in packaging shapes and sizes.

- Reduces packaging material waste compared to other packaging methods.

- It speeds up the packaging process and increases efficiency.

- It protects the product against interventions before the end user and ensures product safety and integrity.

Thanks to its unique horizontal application system, it enables the application of sleeves on unstable or unstable products with complex shapes, providing protection and safety.

It is a concept machine that can be integrated into different line systems and works with maximum efficiency in minimum working area. Thanks to a rotating mechanism, it is suitable for sleeve application on the material regionally or on the whole body with the help of heat. During the process, contact of the products with the conveyor belt is prevented and the products do not undergo any deformation.

A sleeve packaging machine is a machine used in the packaging industry to cover products with a tight plastic film. The machine covers the product with a transparent or colored plastic film and then applies heat to it. After heating, the film shrinks to fit tightly around the product, providing a layer of protection from the elements.

The adaptability of our machine is crucial; they can work efficiently with a wide range of plastic films, including Polyethylene (PE), Polypropylene (PP) and Polyolefin (POF). They are also compatible with environmentally friendly options such as PLA/bioplastic.

- The machine is designed to minimize downtime and improve performance during format changes.

Dedicated tools for each product shape allow simple changes to be made in minutes.

Product format changes can be made quickly and easily with a few keystrokes thanks to pre-created BOMs in the machine control menu.

Advanced Sensor Controlled Operation

Thanks to the sensor-supported input control, it works with the logic of giving sleeve if there is no product. In addition to manual feeding, it can perform fully automatic sleeving by working in integration with the robot-assisted feeding mechanism in order to position the products and sleeve coating properly.

- Fully automatic sleeve application: Maximum efficiency in production.

- Quickly changeable formats: Easy adaptation to different product sizes.

- Sensor-assisted quality control: Separation of defective products from the system.

- Automatic heat tunnel integration: Excellent sleeve coating quality.

- User-friendly touch screen: Easy control of all parameters.

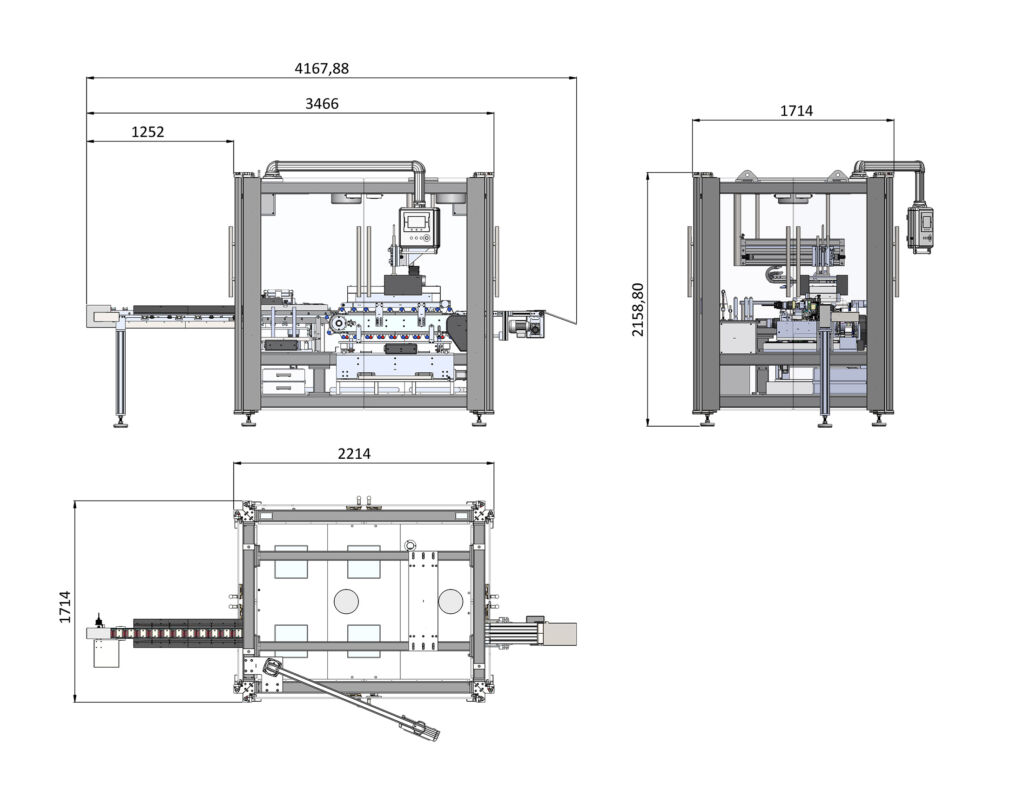

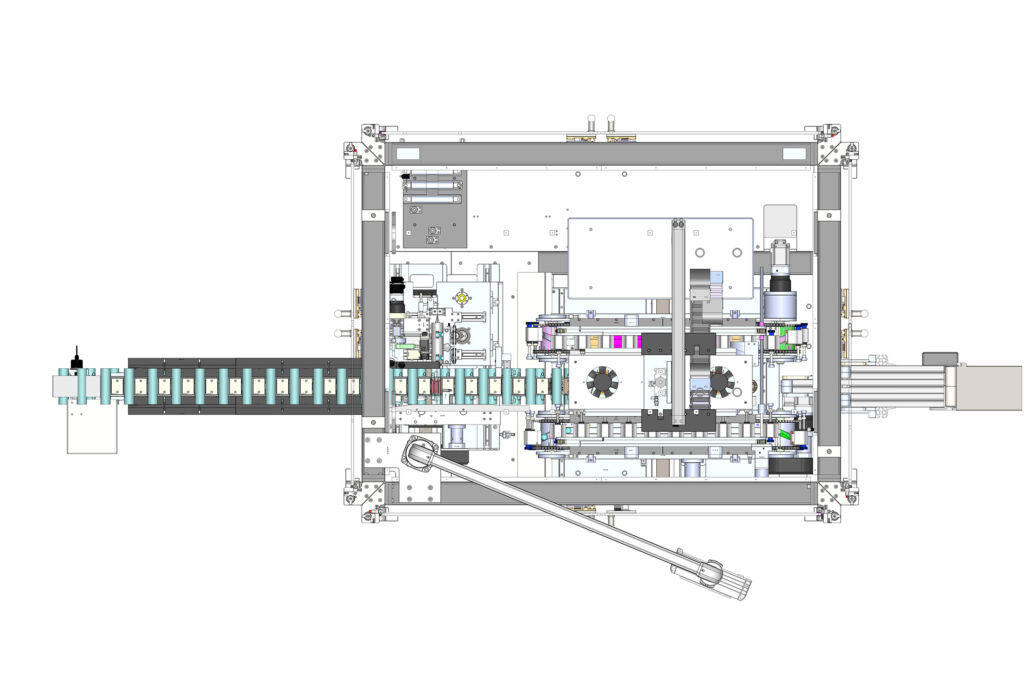

Technical Drawings