Fully Automatic Cylindrical Surface Hot Stamping Machine

It is the ideal solution for manufacturers who want to apply high quality hot stamping on cylindrical surfaces. Thanks to its sensitive, fast and durable structure, it provides maximum efficiency in production processes.

Mascara

Lipgloss

Eyeliner

Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Capacity: | 20-30 pcs/min |

| Air Pressure: | 6 Bar |

| Tube Sizes: | Min.Ø8, Max.Ø20 mm |

| Tube Height: | Min.10 mm, Max.150 mm |

Area of Use

This machine is used for hot stamping on plastic products of various sizes.

- Modular design

- PLC control unit

- Automatic product feeding

- Product availability control system thanks to sensors

- Easy to change mold system

- Automatic product discharge

Our fully automatic cylindrical surface hot stamping machine is designed to apply high quality hot stamping on round surface bottles, jars and tubes used in the cosmetic, pharmaceutical and packaging industries. Excellent results are achieved with automatic feeding, precise alignment and high temperature transfer printing technology.

Fully Automatic Hot Stamping System

Our machine has an advanced hot stamping system that enables high precision printing of cylindrical surfaces. Thanks to the automatic alignment of the products and the even application of the print, the same quality standard is achieved with every print.

Precise Sensor Controlled Operation

Advanced sensor systems ensure the correct positioning of bottles, tubes or jars, guaranteeing error-free application of the print.

- Fully automatic hot stamping system: Perfect alignment and even print quality.

- Fast format change: Easy adaptation to products of different diameters and heights.

- Energy efficient heating system: Optimum temperature control with minimum energy consumption.

- PLC control panel: User-friendly interface.

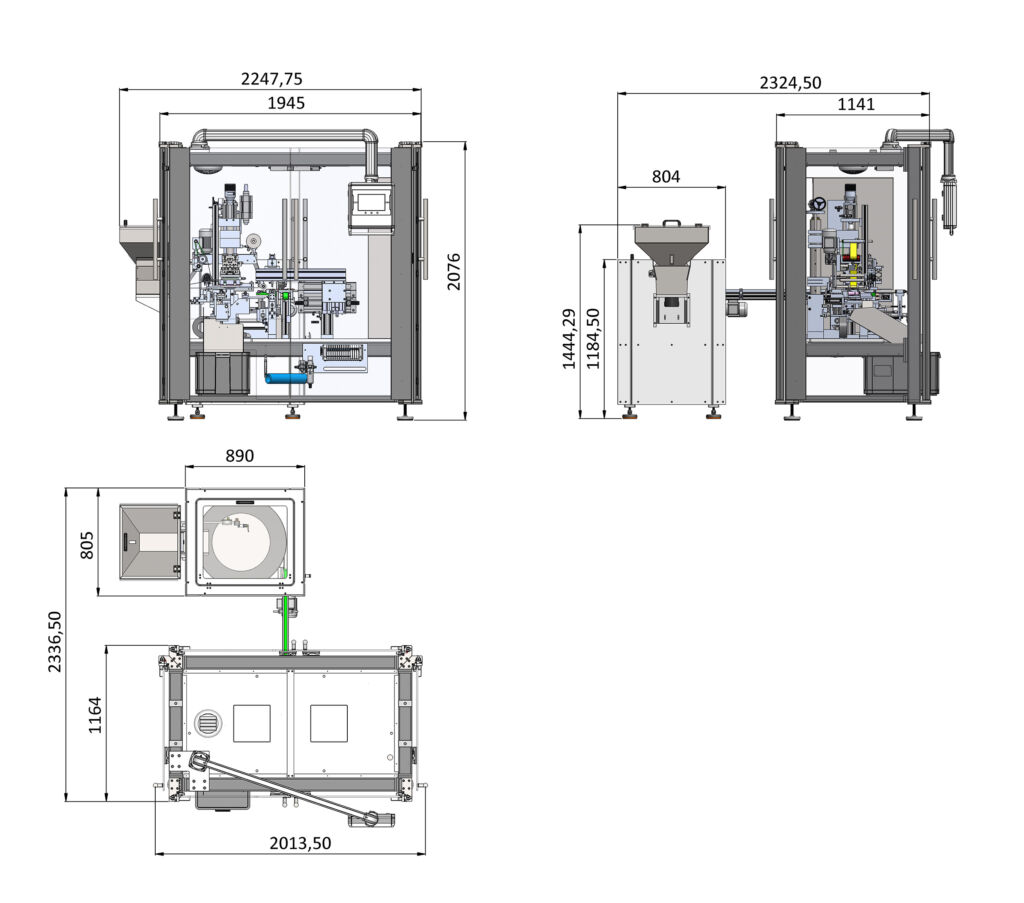

Technical Drawings