Technical Parameters

| Voltage: | AC 380V 3 Phase 50/60 HZ 15 kw |

| Print Sensitivity: | 0.05mm |

| Capacity: | 25-30 pcs/min |

| Air Pressure: | 6 Bar |

| Working System: | Electricity |

Area of Use

This machine is widely used for pad printing on products.

- Modular design, PLC control unit

- 1-6 color printing with 120mm diameter closed dye chambers

- Product attachment bracket that can be easily changed according to the product

- Pad printing on different sides of the product

- Two or six prints in a row with high precision

- The plates on which the plates are placed are movable in XY axes and bearings that provide ±10° rotation of its own axis

- Automatic bumper cleaning apparatus

- Air blowing to allow the print to dry

- Vacuum fixation to prevent product movement

- Thanks to the electric movement, it provides a 25-30% speed increase compared to pneumatic systems and the position accuracy of the dot-sized print

- Compatible with circular printing pads

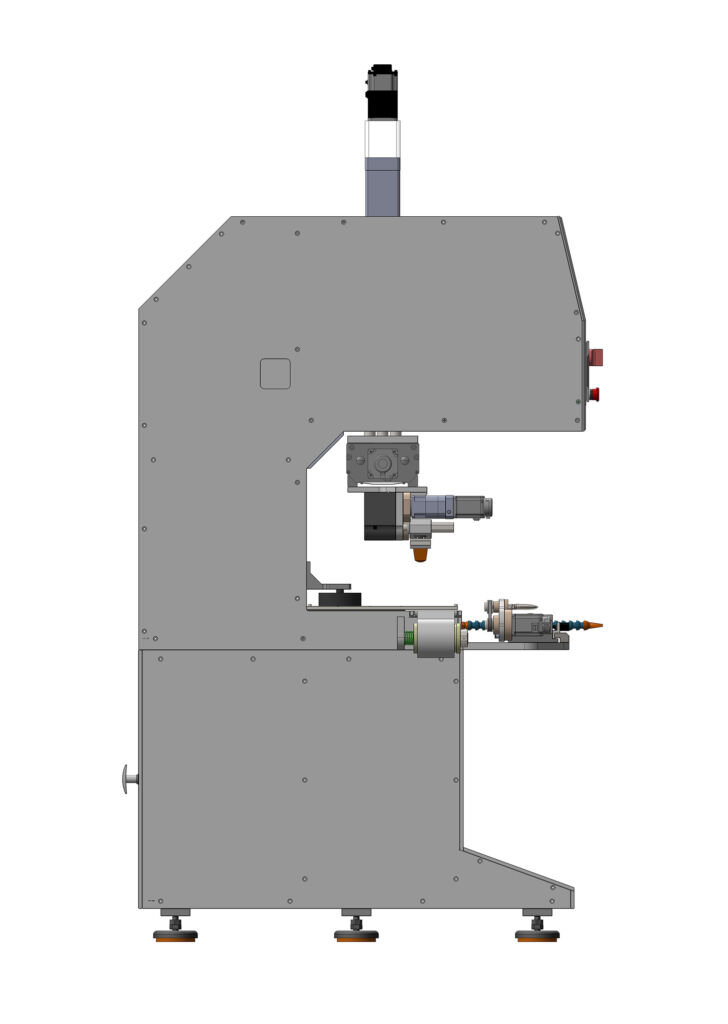

6 Color Full Electric Servo Pad Printing Machine is a system with advanced technology that can make high quality multi-color prints on plastic, metal, glass and other surfaces used in different sectors. Thanks to the high precision servo motor technology, stable, fast and clear prints are obtained.

6 Color Pad Printing System

Our machine has an advanced pad printing system that can print 6 different colors in one process. Printing units controlled by independent servo motors for each color ensure perfect alignment of colors. In this way, even multi-color prints offer error-free and perfect results.

High Precision Sensor Controlled Operation

- 6-color fully automatic pad printing system: Ideal for multi-color printing.

- Servo motor controlled printing units: Maximum precision and clarity.

- Energy efficient servo motor system: High efficiency with low energy consumption.

- Fast format change: Easy adaptation to different surface types and sizes.

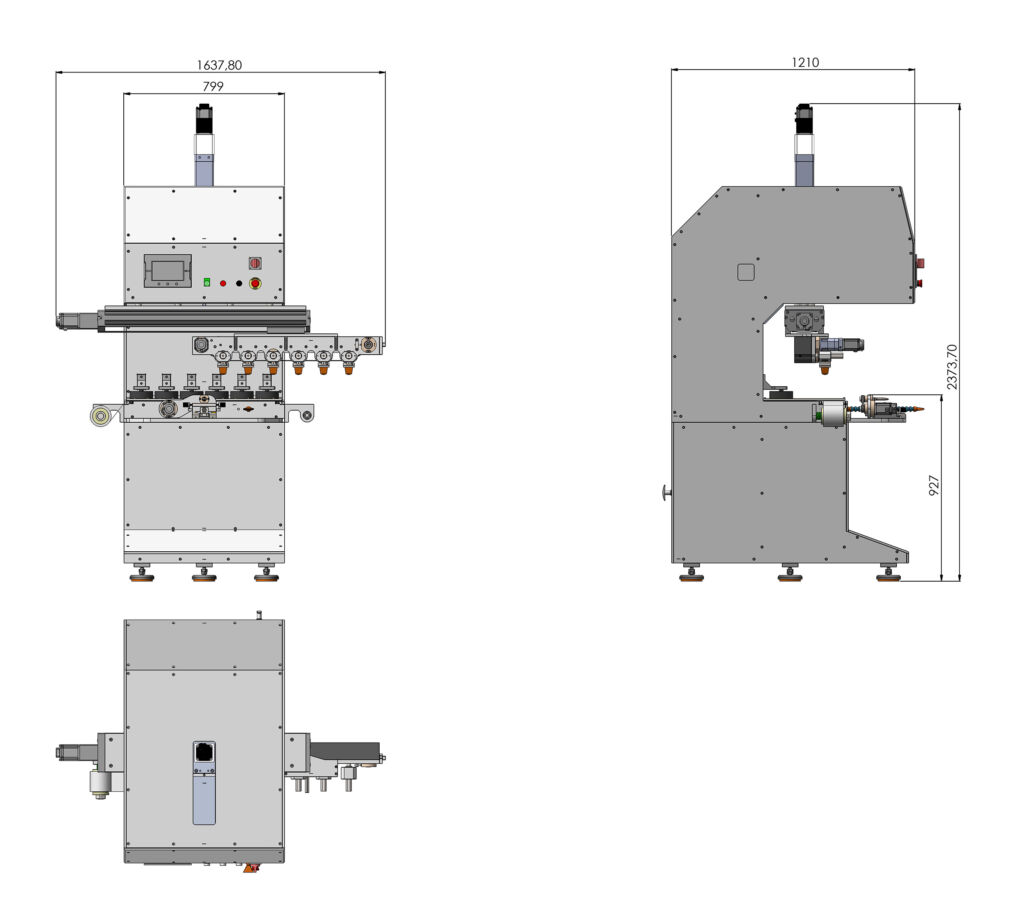

Technical Drawings